Description

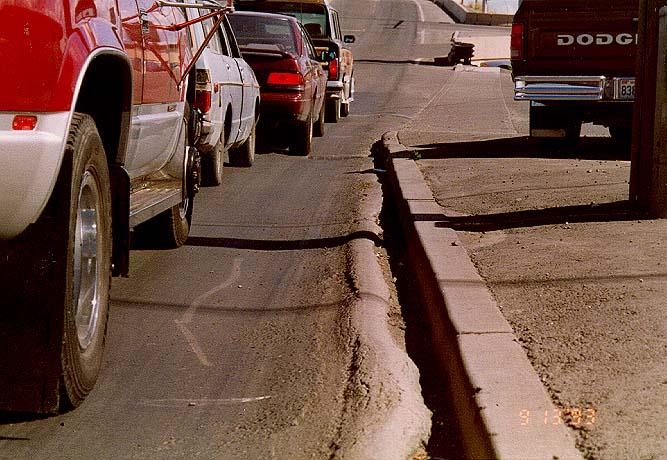

Surface depression in the wheelpath. Pavement uplift (shearing) may occur along the sides of the rut. Ruts are particularly evident after rain when they are filled with water. There are three basic types of rutting: mix rutting, subgrade rutting, and densification.

Mix rutting. Occurs when the subgrade does not rut yet the pavement surface exhibits wheelpath depressions as a result of compaction/mix design problems.

Subgrade rutting. Occurs when the subgrade exhibits wheelpath depressions due to loading. In this case, the pavement settles into the subgrade ruts causing surface depressions in the wheelpath.

Densification. Occurs when there is insufficient compaction during construction and the pavement continues to compact under traffic loading.

|

|

Figure 4. Mix rutting. Rutting is confined to the HMA mixture. Loads push down on the mixture and it flows away from the loading and up. Usually in mix rutting there is a distinctive raised elevation on the edges of the wheelpath. There is no rutting in the subgrade.

Figure 5. Subgrade rutting. Rutting is confined to the subgrade. Loads are distributed through the pavement structure and push down on the subgrade. This further compacts the subgrade in the wheelpaths and the pavement structure flexes down to accommodate the rutted subgrade. Usually, there is a distinctive lack of raised elevation on the rut edges, and the asphalt surface is cracked to allow it to flex into the subgrade rut.

Figure 6. Densification. Rutting is confined to the HMA pavement that continues to compact under the traffic loading. This usually happens shortly after construction and will eventually subside.

Problem

Ruts filled with water can cause vehicle hydroplaning, can be hazardous because ruts tend to pull a vehicle towards the rut path as it is steered across the rut.

Possible Causes

Permanent deformation in any of a pavement’s layers or subgrade usually caused by consolidation or lateral movement of the materials due to traffic loading. Specific causes of rutting can be:

- Mix rutting. Improper mix design or manufacture (e.g., excessively high asphalt content, excessive mineral filler, insufficient amount of angular aggregate particles)

- Subgrade rutting: subgrade deforms under load. This is usually the result of a one or both: inadequate subgrade preparation (e.g., compaction, replacement, etc.) and/or inadequate pavement structure (to reduce the loading on the subgrade to an acceptable level).

- Densification: Insufficient compaction of HMA layers during construction. If it is not compacted enough initially, HMA pavement may continue to densify under traffic loads.

Ruts caused by studded tire wear present the same problem as the ruts described here, but they are actually a result of mechanical dislodging of aggregate due to wear and not deformation.

Repair

A heavily rutted pavement should be investigated to determine the root cause of failure (e.g. insufficient compaction, subgrade rutting, poor mix design or studded tire wear). Slight ruts (< 1/3 inch deep) can generally be left untreated. Pavement with deeper ruts should be leveled and overlaid.