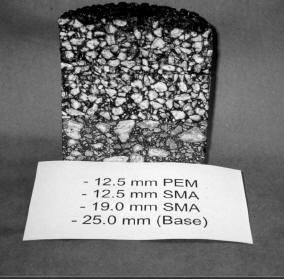

An open-graded HMA mixture is designed to be water permeable (dense-graded and SMA mixes usually are not permeable). Open-graded mixes use only crushed stone (or gravel) and a small percentage of manufactured sands. There are two types of open-graded mixes typically used in the U.S.:

- Open-graded friction course (OGFC). Typically 15 percent air voids, no minimum air voids specified, lower aggregate standards than PEM. See Figure 1.

- Asphalt treated permeable bases (ATPB). Less stringent specifications than OGFC since it is used only under dense-graded HMA, SMA or PCC for drainage. See Figure 2.

Purpose

Open-Graded Friction Course (OGFC)

Used as a surface course only. Reduces tire splash/spray in wet weather and typically results in smoother surfaces than dense-graded HMA. The high air voids trap road noise and thus reduce tire-road noise by up to 50-percent (10 dBA) (NAPA, 1995[1]).

Asphalt Treated Permeable Base (ATPB)

Used as a drainage layer below dense-graded HMA, SMA or PCC.

Materials

Aggregate (crushed stone or gravel and manufactured sands), asphalt binder (with modifiers)

Mix Design

Less structured than for dense-graded or SMA mixes. Open-graded mix design generally consists of 1) material selection, 2) gradation, 3) compaction and void determination and 4) asphalt binder drain-down evaluation. NCAT Report 99-3: Design of New-Generation Open Graded Friction Courses provides a recommended mix design procedure for OGFCs.

Other Information

OGFC is more expensive per ton than dense-graded HMA, but the unit weight of the mix when in-place is lower, which partially offsets the higher per-ton cost. The open gradation creates pores in the mix, which are essential to the mix’s proper function; therefore, anything that tends to clog these pores, such as low-speed traffic, excessive dirt on the roadway or deicing sand, should be avoided.

|

|

- National Asphalt Pavement Association (NAPA). (1995). Thin Hot Mix Asphalt Surfacings. National Asphalt Pavement Association. Lanham, MD.↵