Drum plants, which produce HMA in a continuous manner, generally offer higher production rates than batch plants for comparable cost. Typical production rates for drum plants vary between about 100 tons/hr up to over 900 tons/hr depending upon drum design. Figure 1 shows the basic components of a drum plant and their functions.

Figure 1. HMA drum plant. Scroll over the different components to see descriptions.

Burner

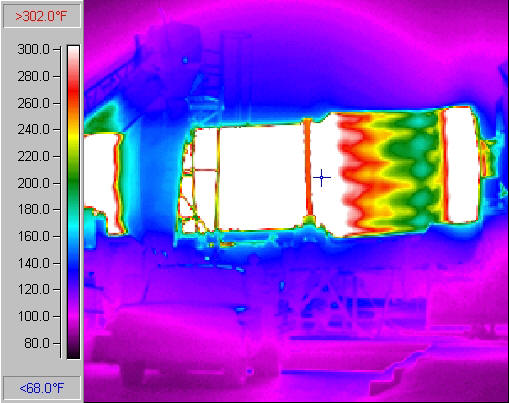

A key component of the drum plant is the burner. Burner fuel can be natural gas, diesel, fuel oil, recycled/reused kitchen oils and more depending upon the burner design. Burners like these can reach temperatures in excess of 760°C (1400°F). Typical HMA temperatures out of the drum are on the order of 150 – 160°C (300 – 325°F).